When replacing roof panels, adhere to region-specific standards for safety and durability. This involves using quality materials, proper installation techniques, and maintaining structural integrity. Specialized tools like magnifying glasses, digital cameras, and laser measures ensure high-quality work, detecting defects early. Thorough inspection is crucial to address misaligned or damaged panels, gaps, and bulges, preventing leaks and mold growth. Re-sealing with automotive-grade sealants is recommended.

Roof panel replacement is a significant investment, making quality control essential. This guide provides essential tips for navigating the process, ensuring durability and safety. We’ll explore industry standards and regulations, equip you with necessary inspection tools, and highlight common issues to watch out for. By following these practices, you can maintain a robust roof system, enhancing your property’s value and protection against the elements. Learn how to ensure every panel meets the highest quality standards in this comprehensive overview of roof panel replacement.

- Understanding Roof Panel Replacement Standards and Regulations

- Essential Inspection Tools and Techniques for Quality Control

- Common Issues to Look Out For During Roof Panel Replacement and How to Address Them

Understanding Roof Panel Replacement Standards and Regulations

When undertaking roof panel replacement, it’s crucial to adhere to established standards and regulations for safety and durability. These guidelines vary by region, but they generally encompass material quality, installation techniques, and structural integrity. Understanding these requirements is vital for ensuring that the new panels not only look like new but also function effectively in protecting your property from the elements.

Roof panel replacement standards often include specifications for materials used, such as gauge and composition, to withstand various environmental conditions. Proper installation methods, including sealing and fastening techniques, are also critical. Additionally, regulations may mandate specific procedures for vehicle collision repair or car restoration projects involving roof panels, focusing on minimizing dent removal marks while maintaining structural integrity.

Essential Inspection Tools and Techniques for Quality Control

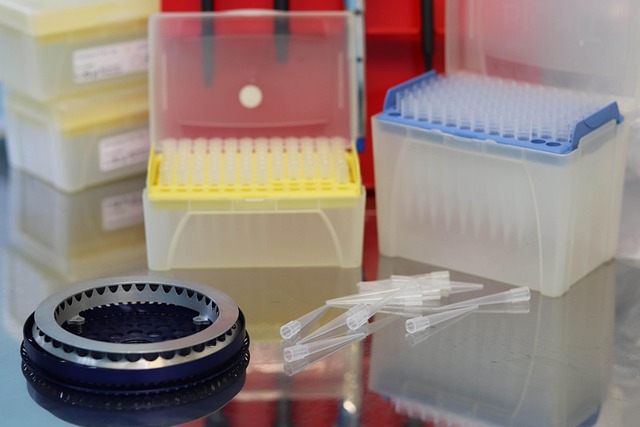

When conducting quality control inspections for roof panel replacements, the right tools and techniques are indispensable. Essential items include a magnifying glass or digital camera to capture close-up images of the work area, ensuring every detail is visible. A level, tape measure, and laser measuring device help verify proper alignment and fitment, crucial aspects in roof panel replacement. These tools enable inspectors to cross-reference against manufacturer specifications, guaranteeing accurate installations.

Additionally, a set of high-quality torches or flashlights illuminates hidden corners and crevices, where potential issues might hide. For detailed visual analysis, an infrared camera can detect heat disparities, indicating problems with bonding or material integrity. Much like in automotive repair or collision repair centers, these tools empower inspectors to catch defects early, ensuring only the highest quality standards are met during roof panel replacement.

Common Issues to Look Out For During Roof Panel Replacement and How to Address Them

During roof panel replacement, several common issues can arise if not addressed properly. One of the primary concerns is misaligned or damaged panels, which can compromise the structural integrity and aesthetic appeal of the roof. Inspectors should look for gaps between panels, bulges, or warping, as these could indicate poor installation or subpar materials. To address these issues, ensure all panel edges are snugly fit together and check for any signs of water damage or corrosion that might weaken the structure.

Another issue to watch out for is inadequate sealing around the edges of the panels. Inadequate sealing can lead to leaks over time, causing interior damage and increasing the risk of mold growth. Proper sealing is crucial, especially in regions with varying weather conditions. If gaps are found during inspection, take measures to re-seal them thoroughly using high-quality sealants designed for automotive repair and car restoration purposes.

When conducting quality control and inspections for roof panel replacement, adhering to industry standards and regulations is paramount. By utilizing the right tools and techniques, and being vigilant against common issues, professionals can ensure a durable, safe, and aesthetically pleasing roofing system. Regular maintenance and prompt addressing of problems will extend the lifespan of your roof, saving you from costly repairs in the long run. Remember, a well-performed roof panel replacement is not just about aesthetics; it’s an investment in your home’s protection against the elements.